do88 Charge pipe, BMW Z4 M40i G29 / Toyota GR Supra A90

370,00 €

Features:

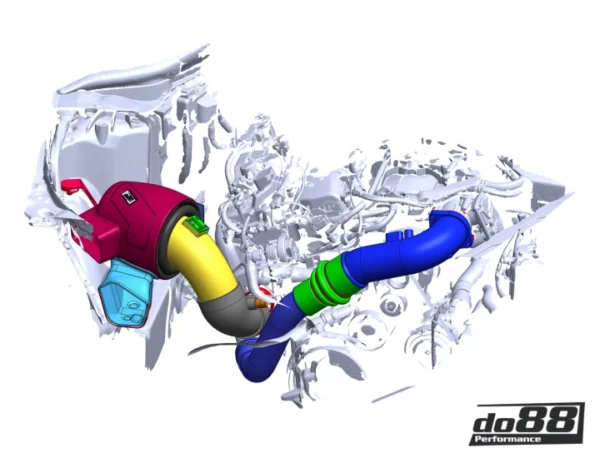

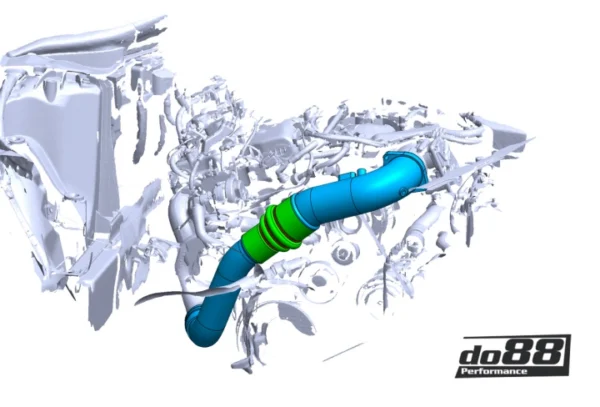

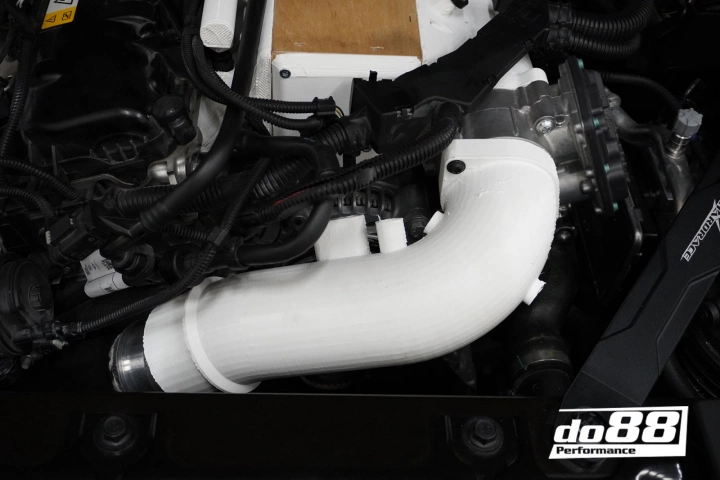

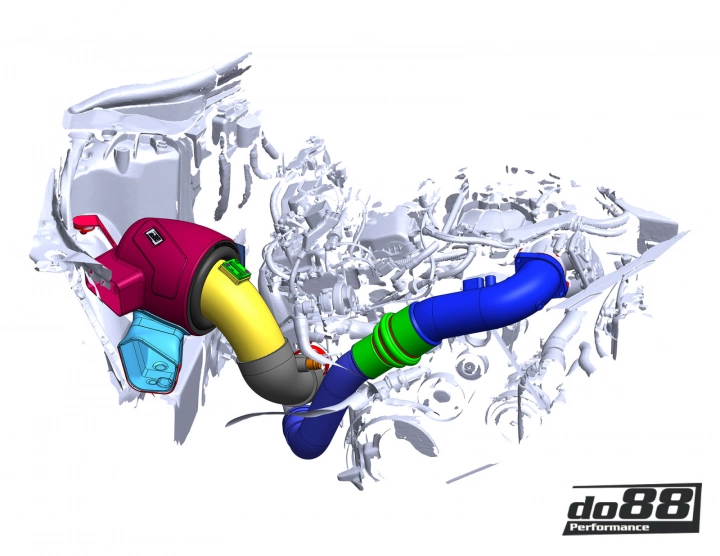

- Flexible hose connection in-between upper and lower charge pipes allowing movement which prevent the hose from popping off.

- Special designed 3-humped reduced silicone hose reinforced with high temperature rated aramid fabric and outer stainless-steel rings.

- Super high quality hose clamps from Mikalor included. These clamps are fitted with an inner-ring inside the clamp that prevents damage to the hose as well as distributing the pressure of the clamp evenly around the hose.

- Better air flow and less backpressure for your engine!

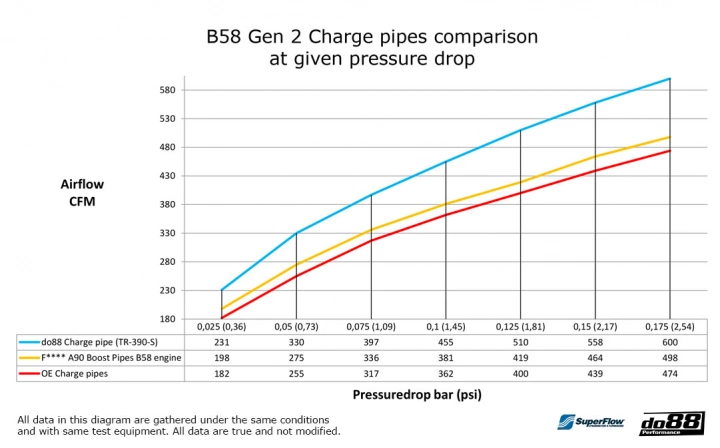

- 27 % more flow than OEM, with 558 CFM @ 150mbar (2.17psi) compared to the OEM 439 CFM.

- CNC machined hose connections with matching inner diameter to the pipe that gives a deformation safe hose clamping surface.

- CNC machined MAP sensor boss, turbo and throttle body connections.

- CNC-machined (2x) 1/8 NPT connections, perfect for methanol injection or as outlets for example boost pressure sensor.

- Two 1/8 NPT plugs are included if you don’t use the ports.

- Mandrel-bent 60mm (2 3/8”) and 76mm (3”) charge pipes coated in a stylish black powder coat.

- Does not interfere with the engine cover.

- Includes all hardware and instructions for complete installation

- Kirjeldus

- Attachment

Kirjeldus

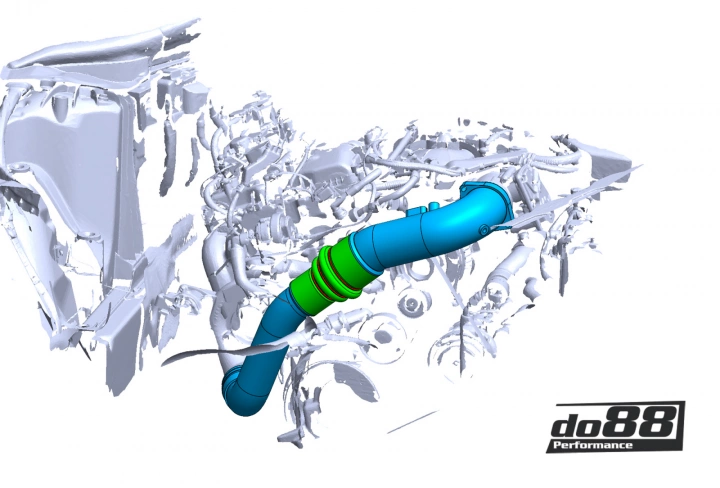

Upgrade your engine with the do88 charge pipe kit for B58 Gen 2 found in Toyota Supra A90 and BMW Z4 M40i!

The B58 Gen 2 engine is fantastic but it has a known reliability issue: its charge pipe. This pipe is known to be fragile and can break even on stock cars during track sessions. If you’re considering tuning your engine, it’s highly recommended to upgrade the charge pipe beforehand.

Many aftermarket charge pipe kits for the B58 engine are available, but in our opinion, most are not properly designed. Many competitors use a basic design: two pipes joined by a straight reducing silicone hose. It’s evident they haven’t understood the importance of handling the thermal movement in this system. Such design is almost certain to cause problems with the hose popping off due to it does not allow movement from temperature changes. A common solution people think of is tightening the clamps more, but this will in most cases break the pipes since it will deform the clamping surface.

But we’ve taken a different approach at do88. For us it was clear the system needs a flexible connection in-between the two pipes which can handle the thermal expansion / contractions. Our solution is an aramid reinforced silicone hose with 3-humps. This hose design allow movement in any direction without folding or putting the connections at stress. To further strengthen our design the pipes have CNC-machined 6063 hose connection ends with 3mm wall thickness. These hose connections won’t deform even for overtightened hose clamps.

Our charge pipes don’t only solve the durability but of course also improve the performance. We designed our pipes with a larger diameter and smooth mandrel bends to enhance the performance. The lower pipe measures 60mm (2 3/8”) and the upper pipe 76mm (3”), they effectively reduce the pressure drop and cut down on turbulence.

Our charge pipe, which connects to the throttle body by its CNC machined flange, has two 1/8 NPT ports suitable for methanol injection or outlets like a boost pressure sensor. Additionally, we provide two 1/8 NPT plugs for those who choose not to use these ports.